Baetsi ba liphaephe tsa tšepe tse entsoeng ka mokhoa o ikhethileng ba nang le seamless ba na le thepa e ngata ea letheba

Kenyelletso ea Sehlahisoa

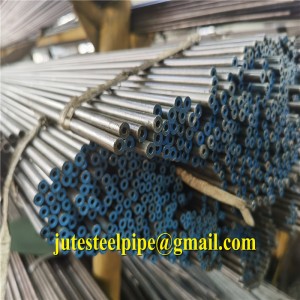

recision phala e khanyang ea tšepe e thehoa ka ho phunya tšepe e chitja ebe e batang.Sehlahisoa se na le melemo ea boholo ba phoso e nyane, e khanyang ka hare le ka ntle, le letlalo le se nang oksijene.E loketse ho sebetsana le lihlahisoa tse nang le sebopeho se ikhethileng joalo ka matsoho a shaft le litepisi.Lihlahisoa tsa rona li rekisoa hantle linaheng tse fetang leshome.Lihlahisoa tsa rona li sebelisoa haholo likarolong tsa mochini, likarolo tsa likoloi le litlhoko tsa letsatsi le letsatsi.

Ka hare ho phala e nepahetseng ea tšepe e khanyang e makatsa ebile e khanyang, 'me ha ho na letlalo la oksijene.Re ka etsa lintlha tse fapaneng tsa liphaephe tsa tšepe tse nepahetseng, liphaephe tsa tšepe tse sehiloeng le ho sebetsa likarolo tse khethehileng tse nang le sebōpeho se khethehileng.Re na le limilone tse fetang 30 tse batang, metjhini e fetang 20 ea ho seha liphaephe le lisebelisoa tse 20 tsa lisebelisoa tsa CNC, tse ka netefatsang ho tlisoa ha lihlahisoa ka nako.

Pipe ea rona ea tšepe e nepahetseng ke mofuta oa thepa ea phala ea tšepe e phahameng ka ho fetesisa ka mor'a ho taka ho bata kapa ho bilika ho chesang.Ka lebaka la melemo ea ho se be le lera la oxide leboteng le ka hare le ka ntle la phala ea tšepe e nepahetseng, ha ho na ho lutla tlas'a khatello e phahameng, ho nepahala ho phahameng, pheletso e phahameng, ha ho na deformation ka ho kobeha ho batang, ho phatloha, ho bata ebile ha ho na mapetsong, e sebelisoa haholo ho hlahisa. lihlahisoa tsa likarolo tsa moea kapa tsa haeteroliki, joalo ka moqomo oa moea kapa moqomo oa oli.

Sebopeho sa Lik'hemik'hale :

| Khoutu Khoutu | sebopeho sa lik'hemik'hale % | |||||

| C | Si | Mn | S | P | Cr | |

| 10# | 0.07-0.13 | 0.17-0.37 | 0.35-0,65 | ≤0.035 | ≤0.035 | |

| 20# | 0.17-0.23 | 0.17-0.37 | 0.35-0,65 | ≤0.035 | ≤0.035 | |

| 35# | 0.32-0.39 | 0.17-0.37 | 0.35-0,65 | ≤0.035 | ≤0.035 | |

| 45# | 0.42-0,50 | 0.17-0.37 | 0.50-0,80 | ≤0.035 | ≤0.035 | |

| 40Kr | 0.37-0.44 | 0.17-0.37 | 0.50-0,80 | ≤0.035 | ≤0.035 | 0.08-1.10 |

| 25Mn | 0.22-0.29 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

| 37Mn5 | 0.30-0.39 | 0.15-0.30 | 1.20-1,50 | ≤0.015 | ≤0.020 | |

Liphaephe tsa tšepe tse nepahetseng li sebelisoa haholo likoloing, lithuthuthu, likoloi tsa motlakase, lik'hemik'hale tsa petrochemical, matla a motlakase, likepe, sefofane, li-bearings, lisebelisoa tsa pneumatic, lipeipi tsa tšepe tse se nang moeli bakeng sa li-boilers tse mahareng le tse tlaase, hammoho le matsoho a matlafatsang, li-bearings, hydraulics, machining le masimo a mang!